BLOWSCAN

Bring your product to market faster.

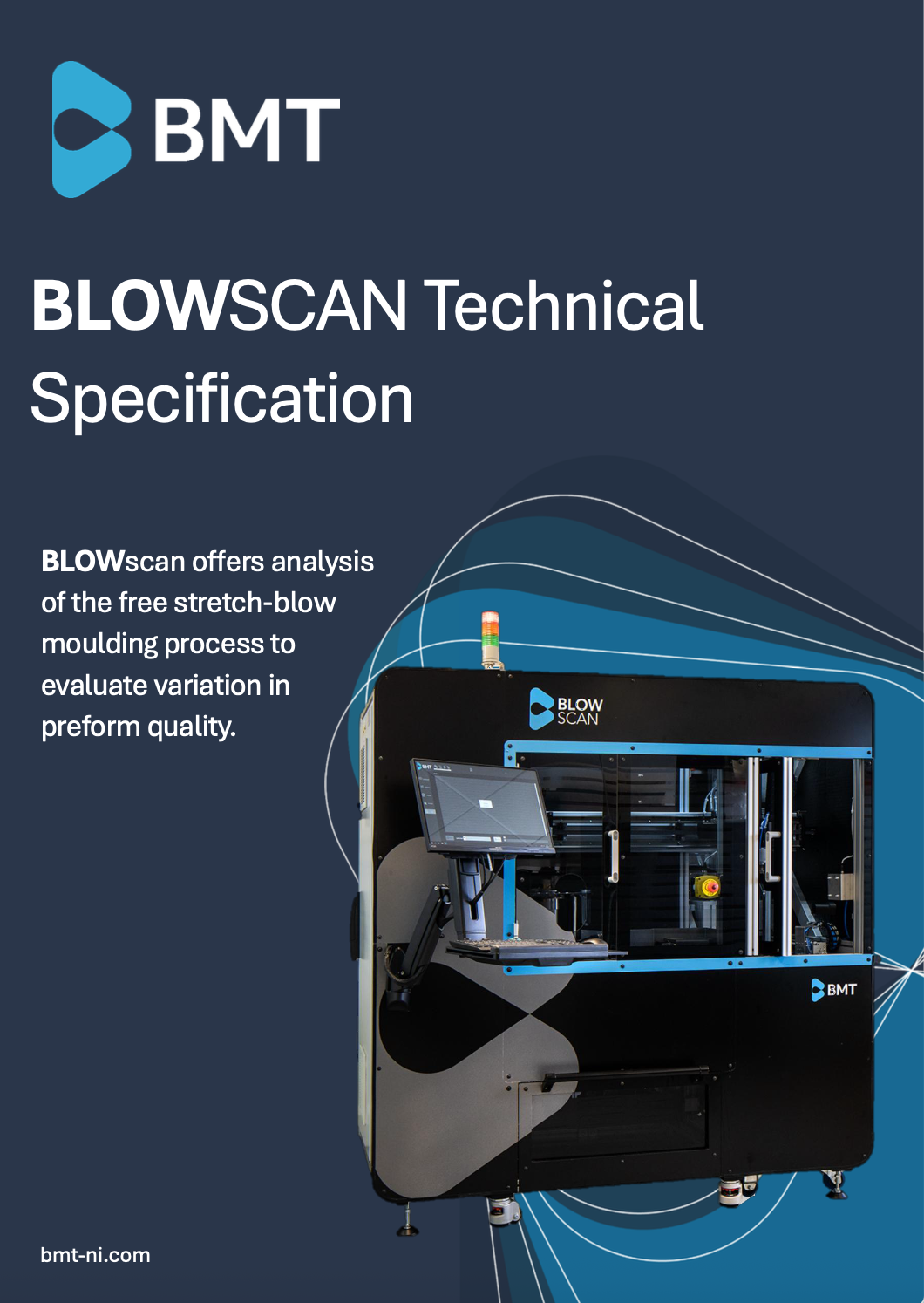

BLOWSCAN offers analysis of the free stretch-blow moulding process to evaluate variation in preform quality.

Explore your preform behaviour and get key data to optimise bottle production.

The benefits of BLOWSCAN

Rapid prototyping

For customer testing to enhance the user experience (before committing to pilot/production runs).

Enables you to compare and assess new designs and unique geometries.

Validated simulations

Access efficient virtual prototyping that accelerates decision making and the development process.

Saves time, resources and money.

Develop sustainable practices

De-risk rPET or bio-based resins before committing to purchase and production (i.e. resin comparison).

Ensures preform, bottle and resin are compatible and optimal.

Production troubleshooting

When batch-to-batch variation is suspected — compare blowing and optical (absorption) behaviour.

Reduce machine downtime, operator downtime, production stall and minimise wastage.

BLOWSCAN can be configured with a custom mould and designed to your specifications.

Controlled heating |

Easily programmable and fully automated

Custom processing |

Processing conditions are variable and user controlled

Modular units |

FREEblow — Bottle shape is captured using a high speed camera.

MOULDblow — SMART prototyping and production validation.

Configurable |

Can be configured to heat the preform and release the preform prior to blowing.

Edge detection |

Bottle shape is captured using dedicated edge detection software.

Data output |

Software performs a statistical comparison between the blown profile and the reference profile

If you are interested in more technical information, please access the specification document.

Click image to open